Service hotline

0572-26670979

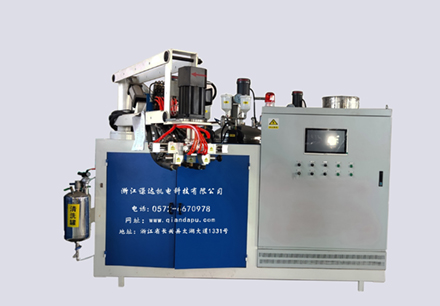

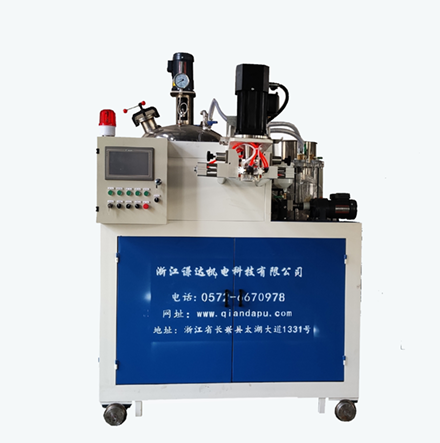

Functional features:

1. Equipped with MOCA melter: just pour MOCA directly into the funnel above tank B to melt by itself, so as to avoid redness and deterioration of products caused by high temperature of conventional electromagnetic furnace or open fire, and improve product quality. (if MDI model, change to mixing device)

2. The visual window is added to facilitate the observation of the physical properties of the original liquid in the storage tank.

3. Reasonable fuselage structure design: perfect control of fuselage size and enhance the structural strength of the frame, and convenient for later maintenance.

4. The heating heat energy of the storage tank is generated by the friction of the atomic movement, with high heating efficiency, fast temperature rise and small heat loss. Because the whole machine discards the heat-transfer oil jacket heating, the machine has small volume, large internal space, convenient maintenance, and more energy-saving and environmental protection.

5. Integral pump seat mechanism contains filter screen, which can effectively filter impurities in raw materials. And has the heating and temperature control function, can effectively control the temperature of the metering pump.

6. Customized metering pump: reasonable tooth clearance and end clearance can effectively reduce the internal leakage of metering pump; special high-strength alloy material can better extend the service life of metering pump.

7. By adopting the buffer connection mode of nylon coupling, a series of problems such as pump jamming and wear caused by assembly concentricity deviation can be avoided to the greatest extent. 8. Speed vector control is adopted for the metering pump motor: encoder is added to the main shaft of each metering pump motor to detect the speed online and feed back to the control system to realize the speed servo (accuracy of one thousandth of a revolution), avoiding the instability of speed caused by low speed torque and load change in the inverter control mode.

9.With a walking mechanism, it can walk back and forth between each pouring station, shorten the distance between the pouring port and the station, greatly improve the working efficiency and save raw materials.

10. Single stage rotary vane vacuum pump: low noise, high efficiency.

11. Head structure assembly:

① needle valve head with adjustable pressure: all components of the machine are controlled by needle valve, and back pressure and needle valve stroke adjustment device are added to effectively control the pouring circulation pressure difference and eliminate the proportion imbalance.

② Exquisite mixing head: the head is made of 316 stainless steel, with good finish. It adopts the most advanced vertical cutting and mixing technology, with even mixing; the mixing chamber is small in volume, saving raw materials and cleaning solvents.

③ Stable color adding and pressing system : due to the small proportion of color paste in the production process, it is easy to cause the pressure in the mixing chamber to be greater than the discharge pressure of the color paste pump, and the color paste appears intermittent or even not. Therefore, a pressure adjusting and stabilizing system is added in the color adding system to ensure the color uniformity of the product.

④ Spindle servo mixing motor: high torque, maximum speed up to 8000r / min.

12. Intelligent control degree of self-developed AI:

① Electrical control: use 10-15 inch touch screen as upper computer, Siemens PLC as lower computer, use pressure and temperature measurement and control module, use PID algorithm for temperature, with higher accuracy (± 0.5 degrees).

② Intelligent proportion test: set the required flow and proportion on the touch screen, and correct the target flow according to the measured value.

③ Remote control: mobile app, computer, touch screen multi terminal Internet connection. Online monitoring data change; remote auxiliary diagnosis and system upgrade.

④ Any combination of multi-component functions: up to 7 components (including color paste and catalyst) can be achieved, which can be used to produce casting elastomer products with different isocyanate systems such as TDI / MDI / NDI / PPDI and different chain extenders.

⑤ One button color paste switching function: the machine can add multi-component (up to 5 groups) color paste independently or at the same time into the mixing head, to achieve CMYK color matching, one button to switch the required color.

⑥ Power off cleaning and discharging function: it can be equipped with built-in UPS power supply, which starts automatically in case of unexpected power off. It can complete the cleaning and discharging of the machine head before the mixture solidifies, so as to avoid that the machine head cannot be disassembled due to the blockage of the mixing head.

⑦ Anti forgetting cleaning alarm function: the time of air washing process can be set at will, and the alarm will be given automatically within the set time after each pouring to prevent the mixture from solidifying in the mixing room.

⑧ Pressure difference comparison: use the change of pouring cycle pressure difference to judge whether the flow deviates from the preset value in the pouring process, fundamentally eliminate the problem of proportion imbalance, and greatly improve the stability of the machine.

⑨ Optional protection functions: over current and overload, lack of phase and zero, flow deviation, loss of components, pressure imbalance, lack of material, lack of cleaning solvent, low speed of mixing head, out of control temperature break couple, low air pressure protection, all faults are displayed on the touch screen, all peripheral input and output electrical faults can be monitored in the system, and quickly find out the fault for auxiliary solution.

15. Optional flow closed-loop control: add sensors at the output end of each component metering pump to monitor the real-time flow online and automatically stabilize at the target value, so as to realize the flow vector control.

Copyright 2019 Zhejiang Qianda Electromechanical Technology co.,Ltd All Rights Reserved 浙ICP备19050343号-1